On Comprehending CAD ModelsPermalink

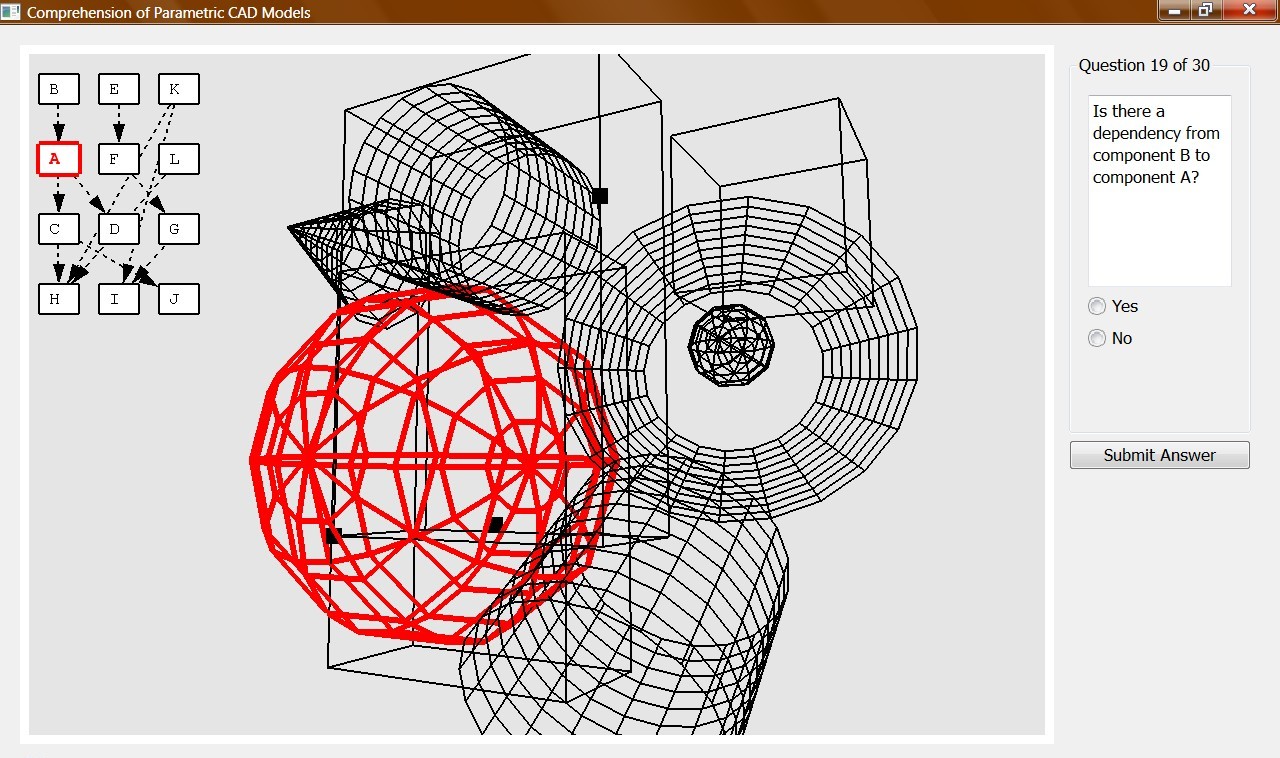

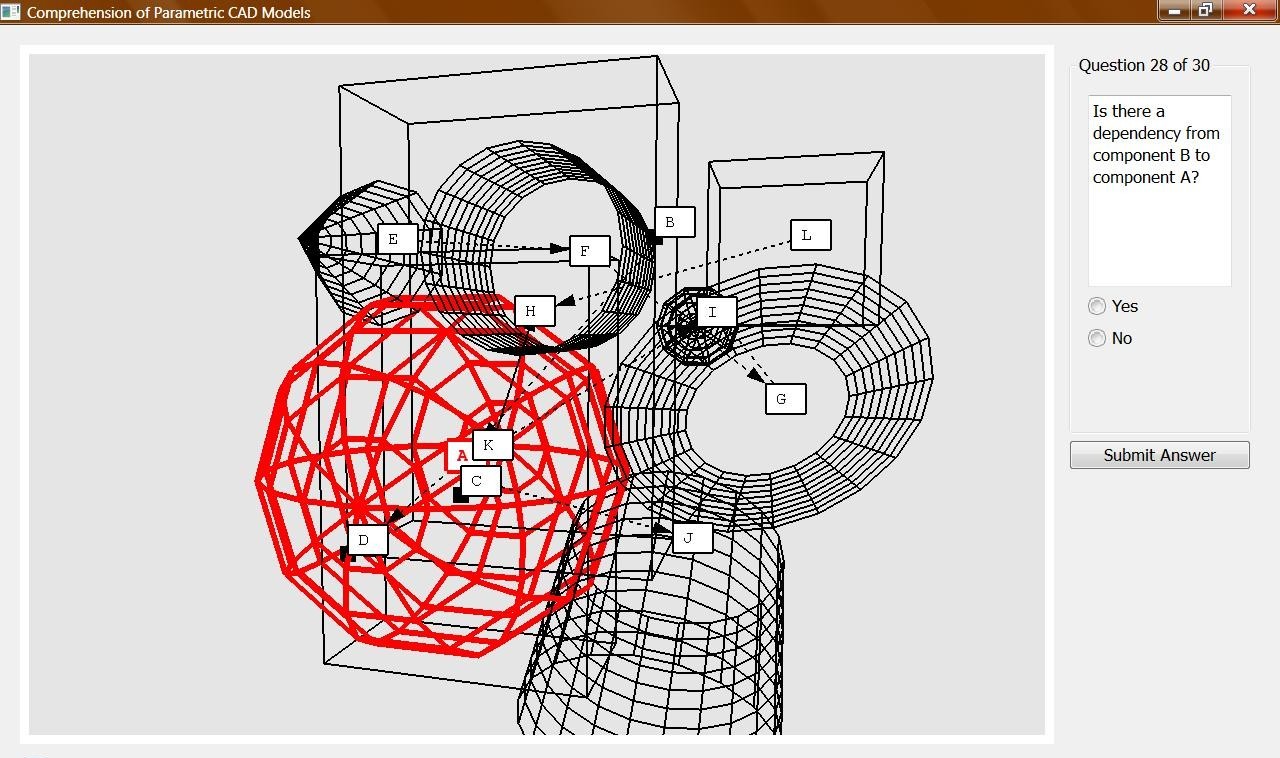

In this study, I developed and experimentally evaluated two GUI prototypes (named “split” and “integrated”) in the domain of parametric CAD modeling. Participants in the study (n = 13) were asked to perform a number of 3D model comprehension tasks, using both interfaces. The goal of the study was to determine which of these two interfaces led to a better comprehension of the 3D model, when rendered using the wireframe visualization mode.

The “split” interface prototype developed for this study consisted of the dependency graph and its associated diagram showing geometric parts, placed side-by-side.

The “integrated” interface prototype developed for this study consisted of one topo-geometric diagram that combines elements from the “split” interface into one unified interface.

Evaluation Study (Quantitative)Permalink

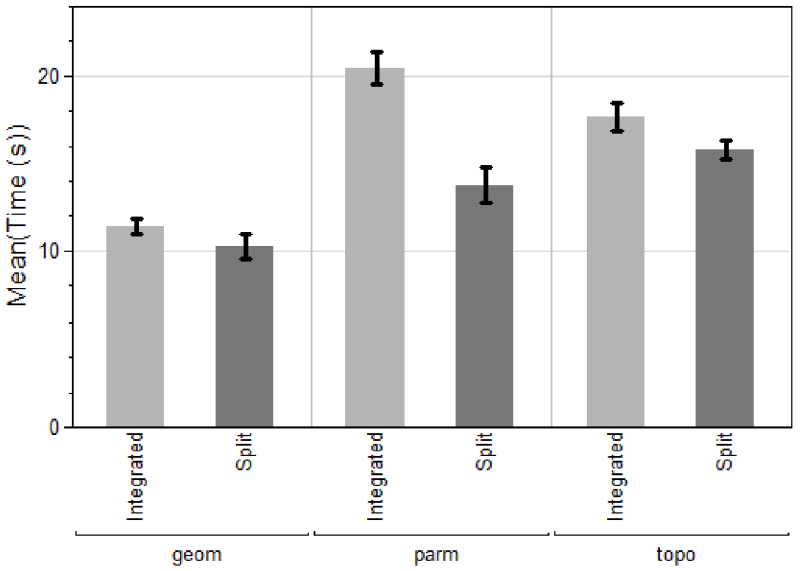

The metrics measured in this study were the task completion times, error rates, and user satisfaction for both interfaces. The figure shows an example of the dependent (observed) variables observed in this study, in this case the mean task completion times.

Mean task completion times, grouped by both interface type and task type.

Mean task completion times, grouped by both interface type and task type.

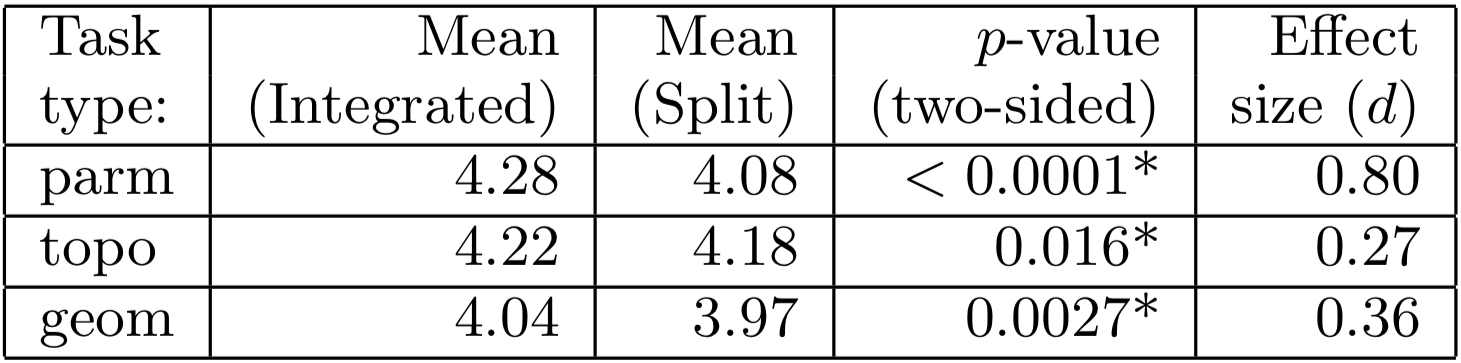

Table below (results of paired-samples t-tests for logarithms of task completion times) shows that all three types of tasks take on the average significantly longer to complete when using the Integrated interface, than the Split interface. Furthermore, the Split interface gets progressively better than the Integrated interface in the following order (c.f. p-values): topo → geom → parm.

Paired-samples t-tests for logarithms of task completion times.

Paired-samples t-tests for logarithms of task completion times.

S. Kolarić, H. Erhan, B. Riecke, R. Woodbury: Comprehending Parametric CAD Models: An Evaluation of Two Graphical User Interfaces, short paper, Proceedings of the 6th Nordic Conference on Human-Computer Interaction (NordiCHI 2010), Reykjavik, Iceland, p.707-710 (2010). https://doi.org/10.1145/1868914.1869010

Vision-Based 3D Manipulation

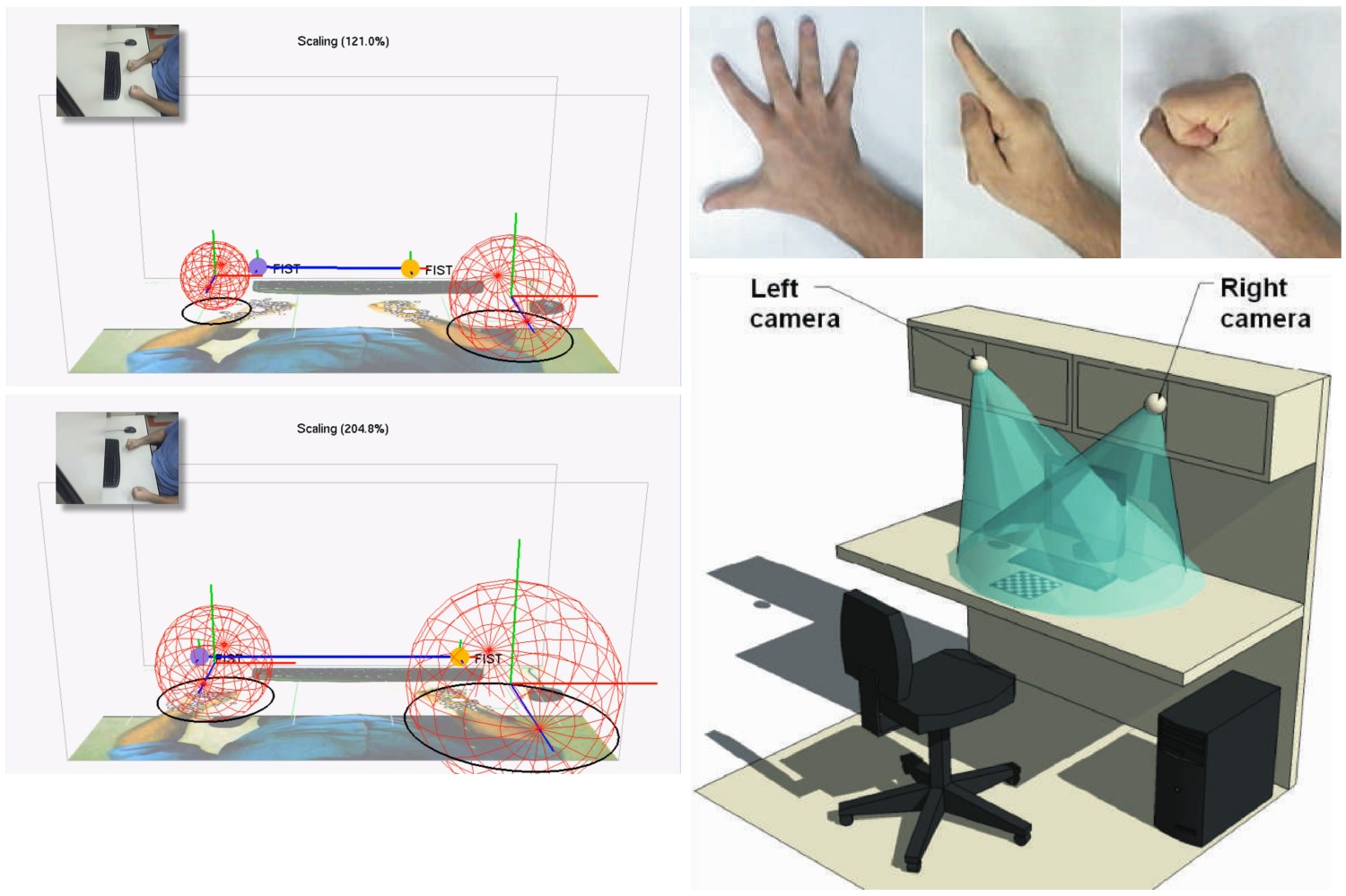

This project was concerned with developing a prototype of an interactive Mixed Reality application for direct spatial manipulation, based on the vision-based recognition of uninstrumented hands. The prototype dynamically integrated both of the user’s hands into the virtual 3D/4D environment, effectively creating a logical 2 × 3 DoF manipulation device. In conjuction with hand gestures, this afforded a number of fundamental 3D manipulation operations like select, deselect, translate, rotate, and scale.

Direct 3D manipulation using vision-based recognition of uninstrumented hands.

Direct 3D manipulation using vision-based recognition of uninstrumented hands.

Evaluation Study (Quantitative)Permalink

Using the system described, I measured tracking-related latencies from 7 to 30ms with just one hand tracked (i.e. with two trackers active), and up to 60ms with both hands tracked (i.e. with all four trackers active). Interaction frame rates ranged from 8 to 15 fps (frames per second).

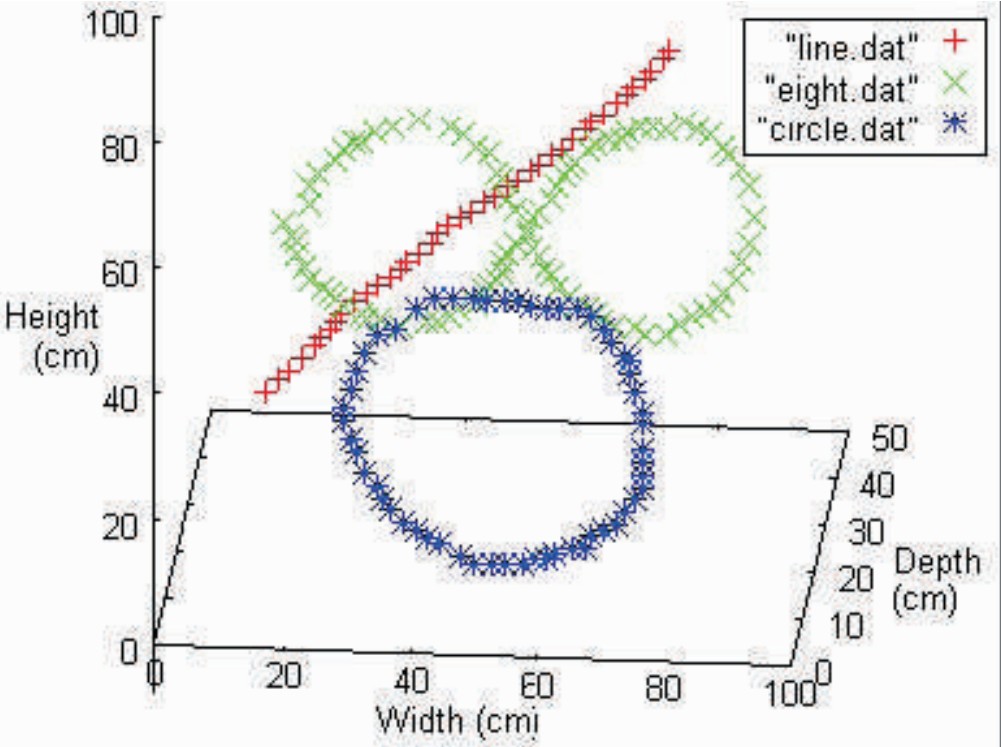

Three-dimensional plot of estimated hand positions, obtained by tracing a line, a circle, and the figure "eight" in space.

Three-dimensional plot of estimated hand positions, obtained by tracing a line, a circle, and the figure "eight" in space.

I also quantitatively assessed estimation accuracy for a hand’s position, as shown in the figure above, from which one can visually deduce the amount of noise present in tracked positions.

S. Kolarić, A. Raposo, M. Gattass: Direct 3D Manipulation Using Vision-Based Recognition of Uninstrumented Hands, full paper, X Symposium on Virtual and Augmented Reality (SVR 2008), Conference Proceedings, João Pessoa, PB, Brazil, p.212-220 (2008). download at CiteSeerX

A Hierarchical Model of Design Knowledge

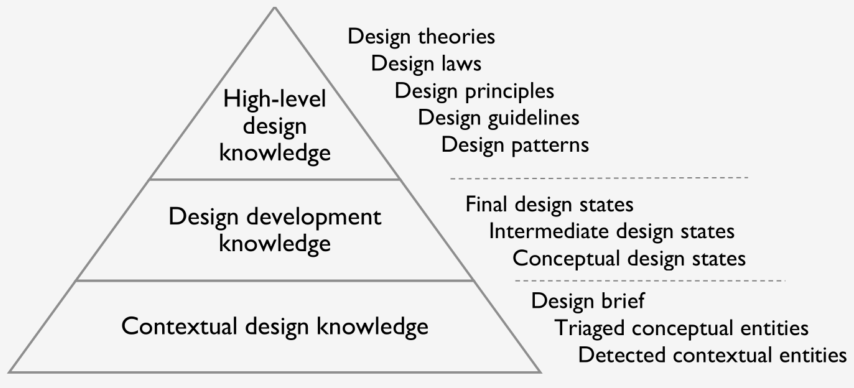

This project is concerned with developing a formal model of design knowledge, named the CDH hierarchical model, which helps design practitioners and design researchers to better understand, explain, map, and acquire various bodies of design knowledge ("BDKs").

The figure below shows the CDH model with its three main levels: context, design state, and high-level design knowledge, as well as some typical BDKs found at each level.

The CDH hierarchy of design knowledge.

The CDH hierarchy of design knowledge.

The paper:

S. Kolarić, J. Beck, E. Stolterman: On the Hierarchical Levels of Design Knowledge, full paper, Proceedings of the Design Society, DESIGN Conference, Cambridge University Press (2020). https://doi.org/10.1017/dsd.2020.330

Data Warehouse + OLAP + custom ETL process

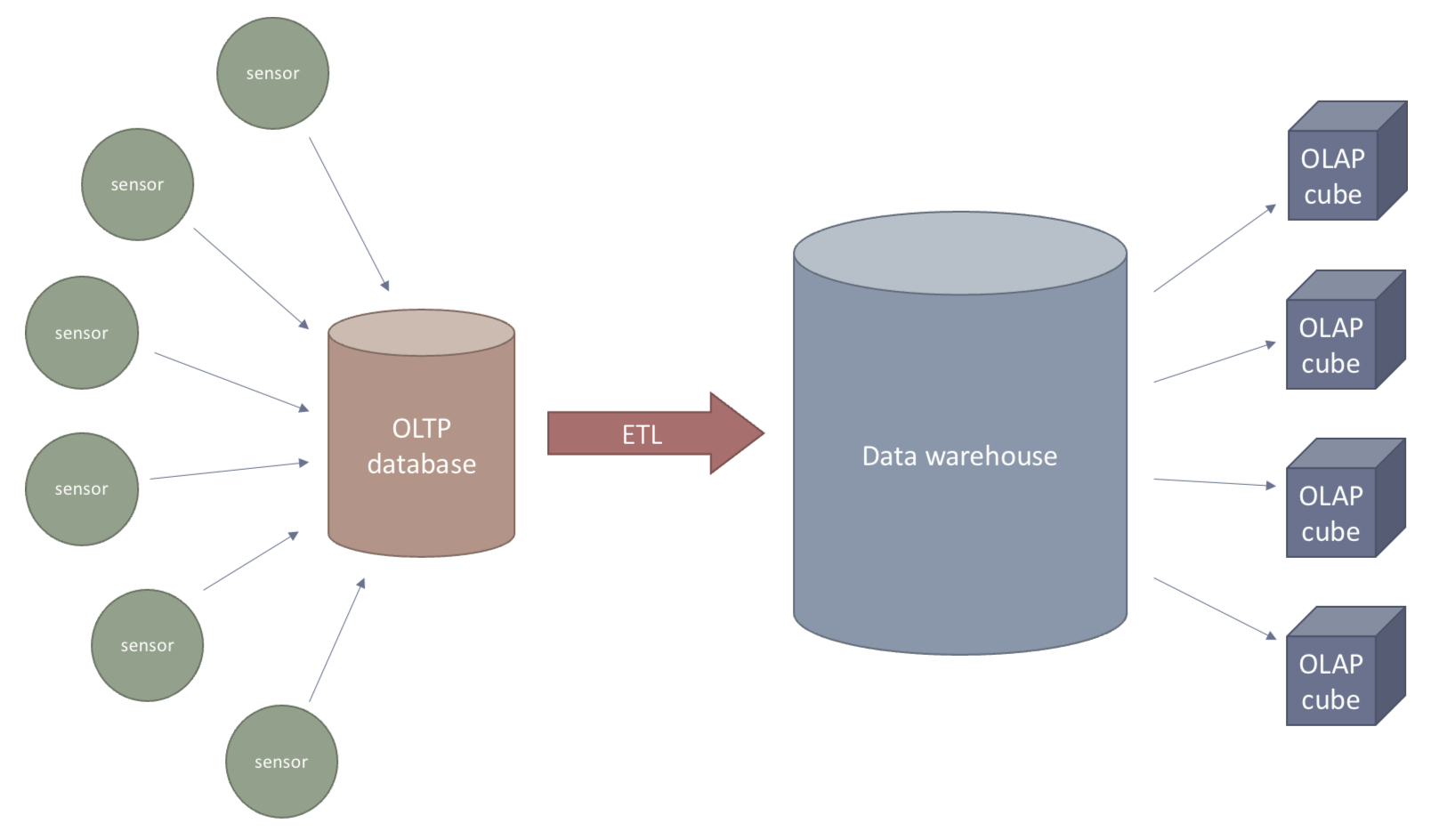

This project was concerned with developing an OLTP database + ETL process + data warehouse + OLAP solution for managing and visualizing various types of industrial data (such as temperature, pressure, and count series) from the manufacturing floor of the main Audi factory in Ingolstadt, Germany.

Data from the OLTP Oracle clustered database was fed into a large, long-term data warehouse (also implemented in clustered Oracle) using a custom-written ETL process in PL/SQL. Finally, this warehousing data was then used to build OLAP cubes, using Microsoft Analysis Services.

The figure below shows the schematics of this data warehousing solution.

OLTP database + custom ETL process + data warehouse + OLAP solution.

OLTP database + custom ETL process + data warehouse + OLAP solution.

Comparative Analysis of Projects

All the projects above juxtaposed in a grid, with pie charts indicating the approximate proportions of:

- Design research,

- Interaction design, and

- Information systems and platforms (includes big data, data science, and machine learning projects).